Intervention

Over 220+ billion pounds of rice husks burn or rot every year.

The husk or hull is the hard protective coating around the grain and it’s discarded during harvest — creating gigatons of greenhouse gasses (GHGs) and poor local air conditions.

Grown globally and possessing unique chemistry, these husks give Glanris a massive supply and scaling capabilities incomparable to any other biochar.

We take these husks and turn them into a designer biochar — Glanris’ Biocarbon. Created with patented clean-tech, Biocarbon has several functional applications both inside and out of climate mitigation.

Technology

-

Our biochar process begins with rice husks.

Using rice husks sets us apart and is important for several reasons, but especially in scale and chemistry.

Scale: Rice husks are the world’s largest agricultural waste product with 220+ billion pounds of it produced annually around the globe.

Chemistry: Their unique makeup allows for our designer biochar modifications — such as the ability to remove metals from water — that set us apart from other biochars.

-

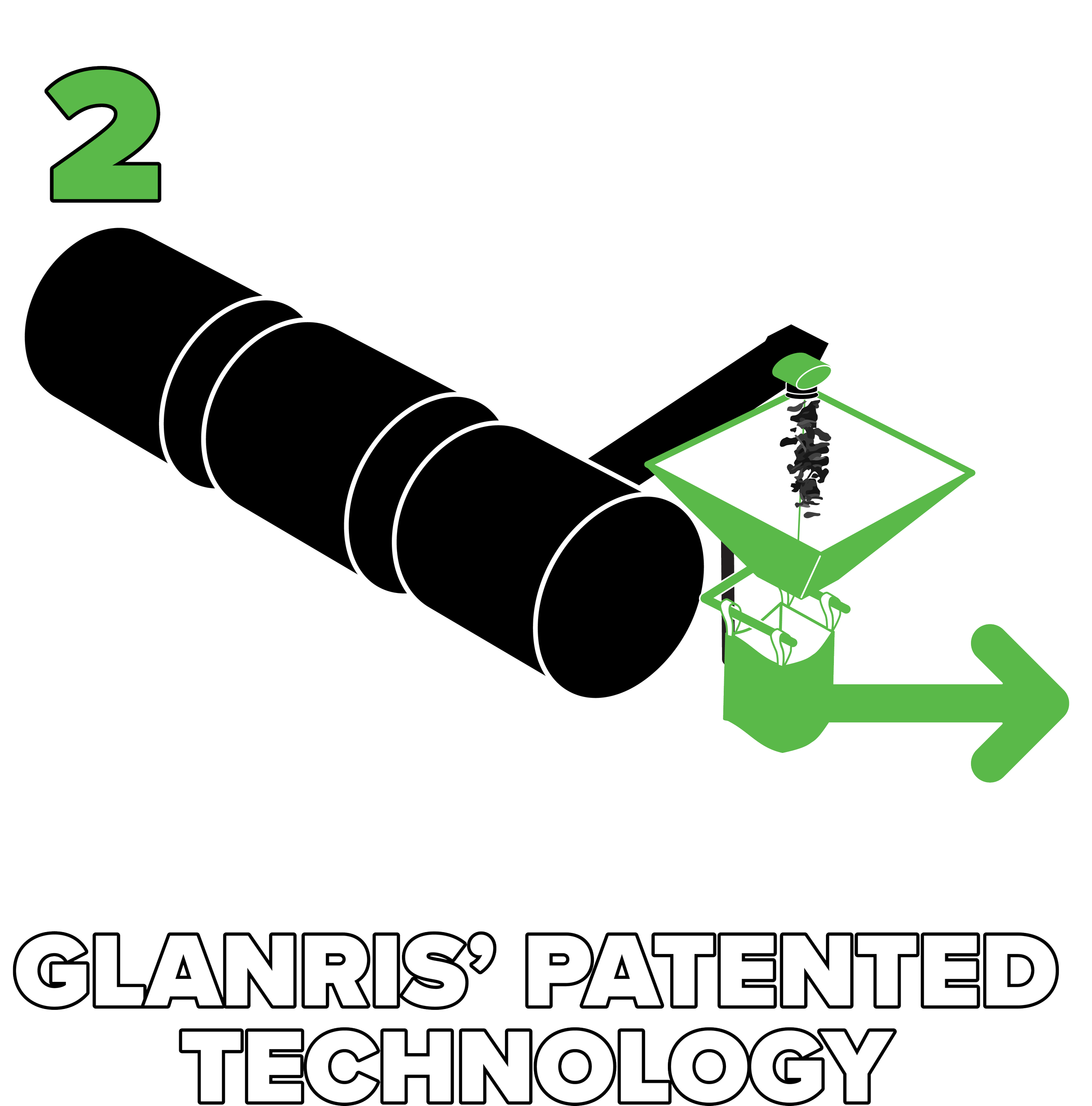

Glanris’ patented clean-tech process using less energy than typical biochar pyrolysis. Pyrolysis is the process of heating a biomass (carbon-based form) without oxygen.

This means that unlike traditional burning, pyrolysis allows the carbon inside the biomass to stabilize and delays its release into the atmosphere. This process basically seals in the carbon content — this is important as pyrolysis stops that carbon from continuing on in the Carbon Cycle.

In the existing system, the carbon content inside rice husks is released and becomes atmospheric carbon dioxide when it burns or rots. By stopping this from happening, we are pulling carbon dioxide from the carbon cycle and locking it into our biochar.

-

Biochar is the resulting product of a pyrolyzed biomass.

Biochar is an ancient process — so what makes Glanris’ Biocarbon biochar different?

Unlike traditional biochar products (wood, coal, etc), we have a sustainable and massive raw supply as well as a wide range of functionality apart from just mitigating greenhouse gasses or as a soil amendment.

We have developed patented technology to both pyrolyze and treat our husks that allow our Biocarbon biochar to filter metals and organics out of water (something novel on its own), and to be used in asphalt, concrete and a number of other applications.

-

Biocarbon is both a tool for climate mitigation and a functional product.

This simple intervention has the power to:

Improve the health of local agricultural communities

Sequester carbon and mitigate greenhouse gasses

Yield a resulting product — Biocarbon — to be used for a variety of functional applications like effective and low-cost water filtration

Allow for sustainable ag-tech practices at no cost to the farmers

Provide a circular economy solution to climate, agricultural, and water issues to rice-growing regions and beyond

Impact

Versatile, affordable, and impactful climate-tech

Biocarbon has been proven effective in its applications — and the technology also provides the fastest and lowest cost solution to scale carbon sequestration.

-

Biochar is the quickest way to scaling up carbon sequestration to a meaningful level.

Glanris’ technology puts this CO2 removal in the fast lane with —

Speed of implementation

Speed of production

Readiness of material

Lowest cost solution

With Glanris’ Biocarbon biochar’s applications in water, built environment, and more, we have potential annual megaton CO2 removal.

-

We provide the lowest cost solution to atmospheric CO2 removal — under $100 per ton at scale.

Direct air capture can cost over $1,000 per ton of CO2 removed.

Glanris’ technology provide an economical alternative to conventional materials within each of our applications — within Biocarbon’s water filtration functionality, we are 1/10th of the cost of competing and non-eco-friendly metals removal technology.

-

WATER TREATMENT: Whether it’s industrial wastewater, municipal drinking water and wastewater, or point-of-use filtration, our Biocarbon media effective removes both metals and organics from water — a novel solution to binary technologies (metals or organics) today. We are more sustainable and a fraction of the cost of the leading microplastic metals-only removal technology. Our Biocarbon is drinking water certified at NSF / ANSI / CAN 61 standards.

BUILT ENVIRONMENT: Because of rice husk’s unique silica makeup, Glanris’ Biocarbon can act as a sturdy binder or aggregate for concrete and asphalt. Not only is this a sustainable alternative, mass adoption of Biocarbon as a binder or aggregate would be able to rapidly scale up our carbon sequestration due to volume.

ENVIRONMENTAL REMEDIATION: Glanris’ Biocarbon biochar media can remove heavy metals without causing further environmental damage. Right now, heavy metal removal filtration comes from expensive resin beads that become environmentally persistent microplastic pollution that will infiltrate our eco-system for millenna.

Product

Scale up your sequestration.

In our 60,000 sq/ft facility located in a transportation hub in the U.S.A., we are ready to ship out whatever you need tomorrow. Lose the 10-12 week lead time.

AVAILABLE IN:

· 300 lb. Supersacks (1 cubic meter)

· 1 cubic foot boxes

· 1 liter sample

Carbon Credits

Offset with confidence.

Glanris is currently on the Puro.Earth CORC Exchange. Purchase available C02 Removal Credits (CORCs) through the link below or learn more about how Glanris has hard science behind our offset capabilities.

Purchase Glanris Carbon Credits →

Read more about our net-carbon-negative certification →

Applications

All from repurposing one crop:

Implementing Glanris’ technology has the power to eliminate megatons of greenhouse gasses annually — it can also bolster access to clean water technology, green-up built environment, and more.

Why Glanris?

“Green” should be versatile, affordable, and easy to implement.

-

SWITCHING TO BIOCARON —

We provide an economical alternative to conventional materials within each of our applications. Using Biocarbon to filter metals out of water is not only an eco-friendly alternative to ion exchange, but saves our customers money. We’re roughly 1/10th of the cost of competing resin technology — without being an environmentally persistent microplastic at exhaustion.

There’s no cost incurred for equipment changes — we’re a drop-in replacement to existing solutions within all our applications.

INTERVENTION + PRODUCT AS CLIMATE-TECH —

We provide the lowest cost solution to atmospheric CO2 removal: under $100 per ton at scale. Direct air capture can cost over $1,000 per ton of CO2 removed.

There’s no cost or hassle for implement satellite Glanris facilities at the back-end of rice mills. It saves rice farmers money and hassle in not having to pay to dispose of hulls, and reducing electric bills if we capture and re-direct energy from waste biogas generated during pyrolysis back to the mill. Removing cost barriers for people to switch to a green technology also means we can scale quickly.

-

SWITCHING TO BIOCARBON —

We provide an affordable and environmentally friendly alternative to all existing solutions within our Biocarbon’s applications. We are a firm believer that green solutions should be low-cost and easy to implement in order to achieve mass adoption and change.

In water treatment, we are a carbon-sequestering circular economy solution — opposite to existing metals-removal treatment, resin-based microplastic beads, that will pollute and permeate our eco-system for millennia.

INTERVENTION + PRODUCT AS CLIMATE-TECH —

We must think of the environmental and societal impact of climate-tech solutions — we do not require plowing down areas for new facilities or mass disruption of an eco-system to scale our technology. We can be placed on the back-end of any rice mill anywhere in the world — providing farmers across the globe a sustainable ag-tech at no cost to the them.

Rice season can be hazardous to some rural agricultural regions. The dense smoke of the harvest causes health issues and poor local air conditions. Glanris’ technology provides an economical and environmentally friendly alternative to burning rice hulls — improving local health conditions of wherever our facilities are located.

-

SWITCHING TO BIOCARON —

You can be secure in using Glanris as an alternative to existing solutions in every single one of our applications.

The effectiveness of our ability to remove metals from water has secured us with drinking water certifications at NSF/ANSI/CAN/61 standards. And testing in our applications within the built environment show that we are a strong binder and aggregate due to the amount of silica in our rice husk base.

INTERVENTION + PRODUCT AS CLIMATE-TECH —

We provide an effective and meaningful carbon sequestration. Proven net-carbon-negative by an independent third party, we remove 1.12 tons of CO2 from the atmosphere for every ton of Glanris’ Biocarbon.

We are a climate tech solution that does not impose any environmental, costly, or societal burden to implement and would be a circular economy solution in rice-growing regions and beyond.

-

SWITCHING TO BIOCARBON —

We are a drop-in replacement for all of our applications — alleviating the burden of switching to green-tech. Speed of switching to Glanris is not just the technical ease of it, but the price point: removing cost barriers to switching to green technology also means we can scale quickly. The more Biocarbon purchased for functional applications, the more carbon we can sequester — and with applications within the built environment and municipal or industrial plants for filtration, we have applications within markets for prime for mass media purchase.

INTERVENTION + PRODUCT AS CLIMATE-TECH —

Biochar is the quickest way to scaling up carbon sequestration to a meaningful level. Glanris’ technology puts this CO2 removal in the fast lane with:

Speed of implementation,

Speed of production,

And readiness of material.

Meet SDG Goals

-

While the production and implementation of our Biocarbon biochar align loosely with 11 of the 17 UN Sustainable Development Goals, the SDGs listed here are ones that we most closely and directly can impact.

By purchasing our Biocarbon we can immediately and directly support systemic-level changes according to indicators and targets outlined in the UN Resolution framework guidelines.

-

Clean Water + Sanitation

The UN estimates as many as 3.5 billion people could experience water scarcity by 2025. We must effectively and economically reuse our wastewater or we won’t have enough water.

Glanris’ Role:

Tool in wastewater reuse for potable/non-potable applications

Pre-filter to improve the efficacy and longevity of desalination systems’ RO membranes.

Environmental remediation to fix growing pollution degrading freshwater aquifers + coastal aquatic ecosystems

Filter industrial discharge water - stopping freshwater pollution

Those most widely effected by water scarcity / security are historically underserved communities - equitable clean water starts with technology at an accessible price point.

OUR BIOCARBON —

Is drinking water certified

Can remove organics and metals

Is roughly the same cost as an economical organic-only removal solution.

-

Industry, Innovation + Infrastructure.

GLANRIS CAN:

Green up industrial practices + infrastructure with biochar.

Help industrial + municipal clients meet their sustainability goals while effectively cleaning their discharge / potable water.

Reduce amount of environmentally persistent micoplastic pollution caused by the typical metals-removal media.

Green up built environment - the silica in our biochar can act as a replacement for sand.

-

Responsible CO2 Emissions + Mitigation.

Our media is certified net-CO2-negative — removing more CO2 from the atmosphere than is released during production. Our LCA data shows 1 ton of Biocarbon media removes 1.12 tons of CO2. This and our official biochar certification allowed Glanris’ listing on Puro.Earth’s CORC Exchange (CO2 Removal Certificates).

Glanris’ technology can address indicators of Goal 12 that focus heavily on sustainable management as well as recycling and re-use of resources and post-harvest losses.

-

Indicators within other Goals where Glanris can assist:

GOAL 11 - Make cities and human settlements inclusive, safe, resilient and sustainable.

11.6, 11.6.1: Greening up infrastructure material (concrete, asphalt)

Filtering storm water

Soil amendment for urban tree planting makes them more resilient

Implementing filtration media large-scale in city municipalities - mitigating emissions + providing sustainable systems

GOAL 2 - End hunger, achieve food security and improved nutrition and promote sustainable agriculture.

2.3, 2.4, and 2.4.1: Providing sustainable ag-tech + reducing the GHGs in agriculture as well as financially bolstering local farmers

GOAL 3 - Ensure healthy lives and promote well-being for all at all ages.

3.9, 3.9.1, 3.9.2 ( +SDG 4.a.1): Alleviating Water, Sanitation and Hygiene (WASH) related issues where clean water can mean the difference between life and death